products

products

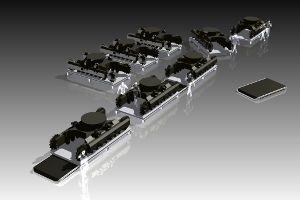

Extra low production line platforms

Organize a flexible production flow without spatial limitations

- unique low access height:

250mm step access - capacity: 10.000kg and more

- integrated lifting system

- radio controlled

- powerful direct brushless drives

- load spreading suspension

- accurate speed control

- all electric and clean technology

- optional: integrated lifting system,

enabling palletized setup - optional: automatically guided

The trend towards a flexible production line has become unmistakable, even for heavy machinery. Factory lay-outs change quickly and conventional rail and chain systems can't operate unaltered for 20 years anymore like they used to. Overhead cranes have their limitations too: safety concerns, range limitation to 1 hall, crossing of cranes is not possible.

Seaqx builds extra low transporters that make it possible to organize such a flexible production plant. These battery operated vehicles can move freely, making it possible to break out of the line setup, differentiate into stations with different passage times for customization, evacuate or isolate products which need extra attention or are faulty, enter end-stations like autoclaves or machining centers and return to the line again, spread production over several production halls,... When the production line needs changes or a complete new setup, these transporters can easily be reused into the new flow, without the need for costly civil works or investment programs.

The transporters can be provided with a lifting system, making a palletized production line possible, which can result in further cost reduction for slower moving lines. The unique low deck height enables direct access for the assembly crew, without the need for steps or stairs. The cost of these vehicles makes it worth to considering implementing this self-evident solution.