products

products

Self Propelled Modular Transporters

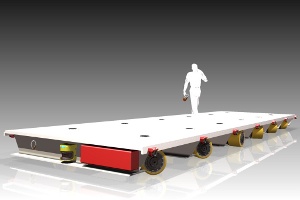

The all electrical indoor SPMT

- modular concept

- all functions integrated in proven, standard drive modules

- capacity: from 20 to 300 ton+

- robust, custom made frame

- tandem operation of multiple transporters

- fully omni-directional

- integrated lifting system

- radio controlled

- optional automatic guidance

- no gas or diesel motor

- all electric and clean technology

- very competitive price/axle-line

The SPMT (self propelled modular transporter) is a classic solution for heavy load transport. It is versatile, extendable and often the only viable solution for large structures. However, the classic SPMT has some drawbacks: it is ill suited for indoor operation due to its combustion power source. It has a high deck height, making access to the cargo difficult or requiring extra lifting systems to put the load onto the SPMT. It's load capacity/meter is not optimal and it needs a lot of space. Many SPMT types are not fully omni-directional and it is not easily automated. Their hydraulic circuits of the hydraulic motors experience high pressure peaks which often leads to oil leakage, the same goes for the hydraulic suspension. The classic SPMT requires a high maintenance schedule resulting in high costs. On the whole they come not cheep.

Seaqx develops an indoor SPMT concept that deals with a number of these drawbacks. It is based on the Seaqx omni-directional drive module. Maintenance free electrical motors make it possible to avoid all oil hydraulics. All functionality — traction, steering, lifting and controls — is integrated into these drive modules. A number of these tested and proven modules are integrated into a passive, custom made steel frame, with only a battery pack and a central control cabinet to make a complete transporter. Electrolyte circulation increases efficiency and eliminates the need for a separate battery charging room.

The drive modules are extremely compact, increasing the capacity/axle-line. Their low height makes directly accessible transporters possible, with deck-heights lower than 400 mm. The Seaqx SPMT can pick up palletized loads directly from the floor. It's sturdy deck is also suited for direct crane loading, while integrated suspension protects the drive modules from overload. Wireless communication enables easy tandem operation, making capacity virtually unlimited upscalable.

Cost is taken into account in every step of the design process, resulting in a very competitive price setting/axle-line.