products

products

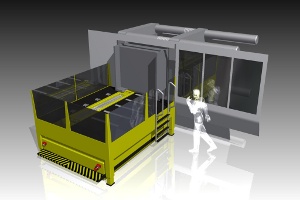

Quick mould and die changers - QMC & QDC

Load and unload your moulds or dies in no time

- independent vehicle & transfer platform

- capacity: from 5 to 100 ton+

- based on Seaqx standard drive modules

- fully omni-directional

- powerfull all-electric tranfer unit

- manual, semi-automatic or full-automatic mould or die tranfer

- precision up to 1 mm

- radio controlled

- all electric and clean technology

The people of Seaqx are specialists in the area of quick mould change systems (QMC) and quick die change systems (QDC). We have designed, built and put into operation dozens of change systems: full-automatic rail-bound systems, radio operated systems floating on air bearings, changers on wheels, manual systems, from 5 tons, over 3x50 tons up to 200 tons. We have designed them with hydraulic, pneumatic and electric push-pull systems and driven rollers as well. We've built 2-station changers and continuous systems linking up to 7 injection moulding machines, systems that unload and load several 40 ton moulds in under 20 seconds.

The extensive experience we've built up through the years is invaluable when building new change systems. The Seaqx mould or die changers are split up in a vehicle part and a static platform with driven rolls or passive rolls and a telescopic transfer arm. The vehicle is a standard Seaqx vehicle and can be used for mould transport while the change system is in operation.

This approach has several advantages: the number of transporters and transfer platforms can be adapted to the needs, one can start with one transfer unit only for one IMM, initially move it by crane, until the number of IMM's requires a more sophisticated means of transport. One can instal several transfer platforms, and move them on occasion when needed on a slower cycle IMM. One can transport moulds between halls, one can couple two transfer platforms to increase change speed (one empty platform to unload, one loaded platform that contains the new mould or die), even in tight spaces,... This approach also increases reliability and upgrade-ability.

Our transporters allow for the automation level of rail-bound transporters with IMM or presses in line, but on top allow for complete lay-out flexibility, with production spanning several halls and a separate mould- or die-storage area.