products

products

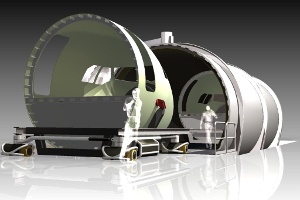

Autoclave loading

Integrate autoclaves seamlessly in your production line, eliminating extra handling

- ultra-low vehicle height -250mm, maximazing available autoclave space

- capacity: from 10 to 100 ton+

- fork design or pallet transporter

- fully omni-directional

- narrow wheel track

- integrated lifting system

- mechanical guidance options

- precision up to 1 mm

- radio controlled

- all electric and clean technology

Loading an autoclave or an oven is often a tedious and time-consuming task: products are transported to the autoclave location, transferred by crane onto a rail cart. When the rail cart is full a towing unit pushes the rail cart into the autoclave. The reverse process goes for unloading as well.

Seaqx offers a solution to make autoclave loading more efficient: the same vehicle that transports the product through the assembly line (winding stations, layering stations, milling stations,...) can be used to introduce the products directly into the autoclave, no need transferring them on to other carts, and streamlining production flow. Using the integrated lifting stroke, the product can be picked up and moved, directly from floor level or using a pallet or jig depending on the kind of load.

To accomplish its task successfully, the autoclave loader needs to be as low as possible, to maximize available space inside the autoclave. The Seaqx autoclave loader can be as low as 250 mm. The same autoclave can be used to cure larger parts, before the acquisition of a larger one needs to be contemplated.

The load can be picked up from the sides using a U-shaped transporter, or from underneath using a regular transporter. The wheelbase of the drive units is narrow, so only two steel tracks need to be provided inside the autoclave or oven. Mechanical guiding is optional, safeguarding the autoclave and load under all circumstances.

Seaqx builds autoclave loaders that are custom designed to specific constraints. The Seaqx re-sizable multipurpose vehicles are also suited very well as autoclave transporters and oven loaders.